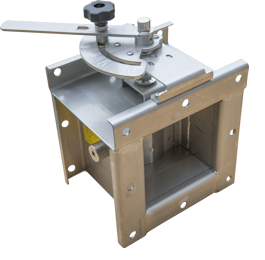

Fire Dampers

What is it?

DYNAC’s range of Fire Dampers are proven high performance products precision engineered for use in the most arduous conditions and hostile environment, independently tested and verify by the World’s leading Classification and Certifying Authorities.

Fire Rating:

Our Fire Dampers are engineered to meet the highest safety standards, providing fire resistance for:

- Hydrocarbon Fires: H120, H60, H0

- Cellulosic Fires: A60, A30, A0

Approved for Use In:

- Offshore Oil & Gas Platform

- Offshore Drilling Rigs

- Oil & Gas Tankers

- Cruise Ships and Ferries

- Onshore Petrochemical Installations

Our Control Options

Pneumatic

The damper is operated by one or more pneumatic actuators. These are designed to fail closed on loss of pneumatic supply by means of an integral spring arrangement. The damper operates from a single air source in the range 4.0 to 10.0 bar.

Manual

The damper is manually set/reset by means of a latching arrangement and fail closed under spring tension when triggered. No power or Pneumatic supplies are required.

Electric (hazardous area)

The damper is operated by one or more motorized actuators. These are fitted with and integral spring and are arranged to close the· damper on loss of the electric supply. The damper is suitable for a range of power sources.

Electric (safe area)

Designed mainly for heavy industrial applications, the damper is operated by one or more motorized actuators. These are fitted with an integral spring and are arranged to close the damper on loss of the electric supply. The damper is suitable for a range of power sources.

Fire Test Criteria

Our Fire Dampers undergo rigorous testing to ensure optimal performance and compliance:

- Test Duration: 120 minutes (fire insulation and structural integrity).

- Standards:

- Conducted according to the Hydrocarbon Temperature & Time Curve as defined by the Department of Energy.

- Compliant with IMO Resolution 754(18).

- In accordance with BS 476 Part 20.

- Testing Orientation: Tested in both horizontal and vertical fire test panels, as required by IMO Resolution 754(18).

- Damper Sizes Tested:

- Largest: 1200 x 1200 mm.

- Smallest: 100 x 100 mm.

- Testing on a range of sizes is a mandatory requirement under IMO Resolution 754(18).

Our Fire Damper Range

Dampers can be manufactured to meet any duct size and where the apertures are greater than 1200 x 1200mm, there are supplied in multiple unites sub divided by vertical mullions and/or horizontal transform.

- FIRE DAMPERS (ELECTRICAL OR PNUMATIC)

- SHUT OFF DAMPERS (ELECTRICAL OR PNUMATIC)

- MODULATING DAMPERS (ELECTRICAL OR PNUMATIC)

- VOLUME DAMPER

- PRESSURE RELIEF DAMPER

- NON RETURN DAMPERS